Material Analysis

They call it Material Science.

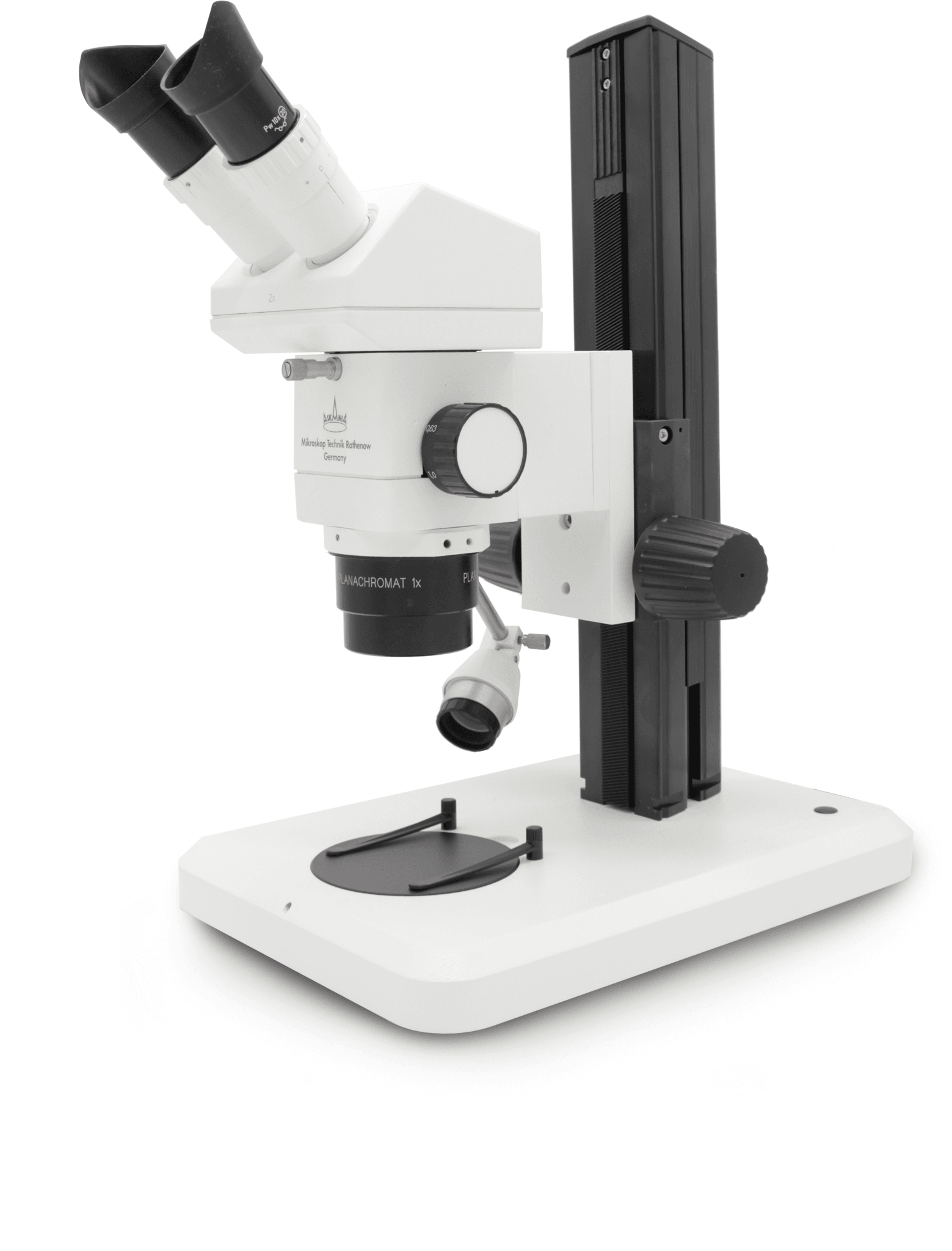

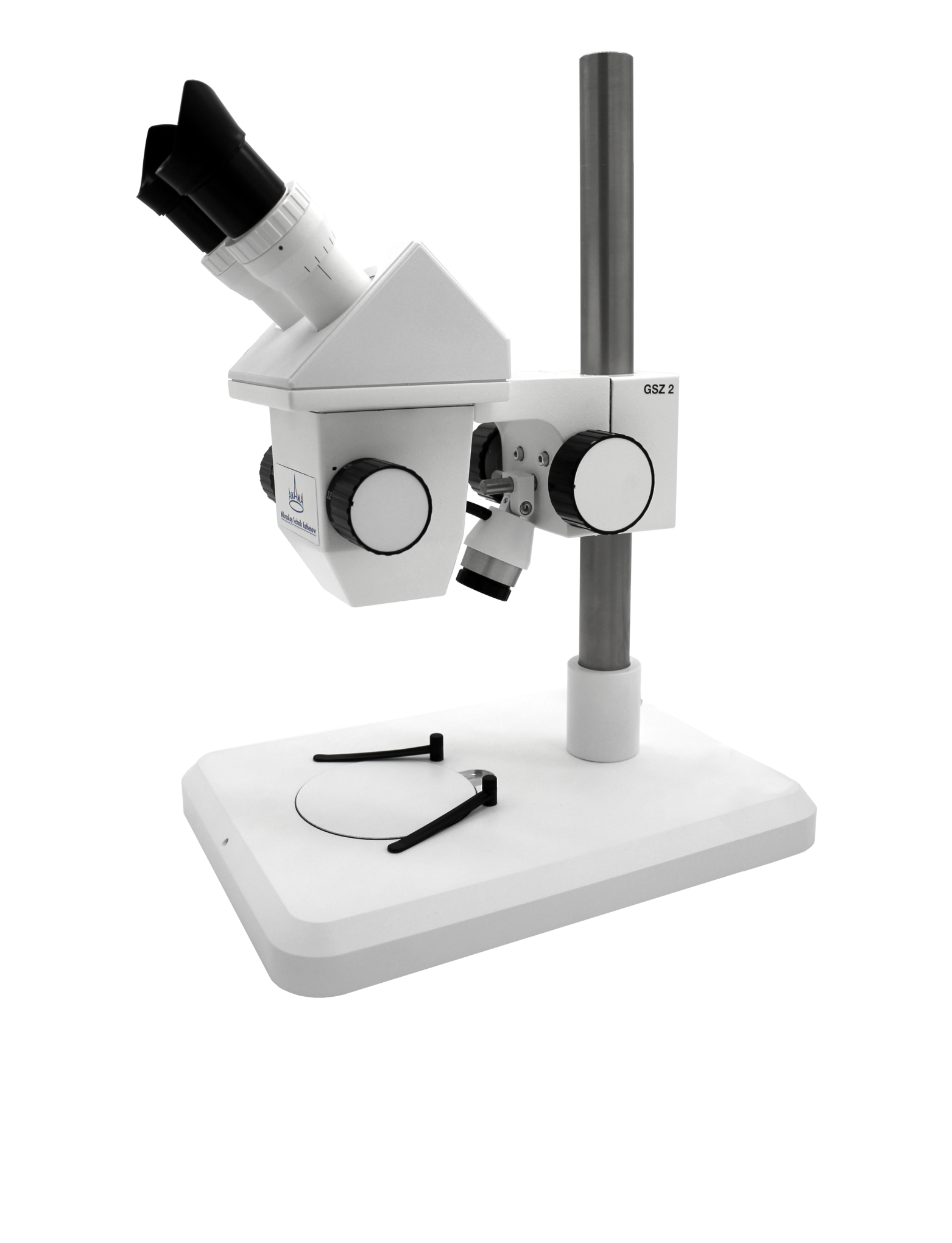

In quality control, analyzing single products is not enough. To obtain a fully transparent production, that is not only error-resistant but also flexible and faster adjustable for changed conditions, machines and tools have to be put under the magnification glass aswell.

Thanks to modern microscopes, you can pin-point the exact moment, situational condition and interlocked results from punctual change of material attributes- be it overheating, vibration or laser malfunctions.

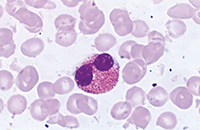

And in geology, you can apply the same precise methods to reconstruct the forming and weathering of materials which are as old- or sometimes older- than our world. Sorting minerals by color is a traditional and well-established method indeed, even more so when you start to apply it at the scale of micrometric elemental units. Analyze planetary sedement and grown crystals with colorfidelity and no smears or refractive blurs. Discover not only the material of each region, but ultimately how that region came into being- a process of millenia hidden in a single image.

In the textile industry, we want to produce robust, flexible, soft, perhaps reflective and perfectly color-matched weaves. Exact documentation of woven structures are absolutely neccessary. Nodes, pattern and errors in latices, thickness of fibres or inclusions are just a few of many aspects of textile geometry. Analyze not only the fabric, but also the tools which made them, by illuminating and projecting the very edges of microscopic thread nozzles.

In each case, sample preparation is key. Thanks to modern polarization methods, you can filter out reflexes and save hours of work that would otherwise go into graining or staining polished surfaces of samples. LED illumination devices ensure a safe, economic and passive light which reveals details in the sample without heating it up even in the brightest translucent illumination modes.